OptoSort® series APOLLO

Sorting machines for user-defined sorting of mining products.

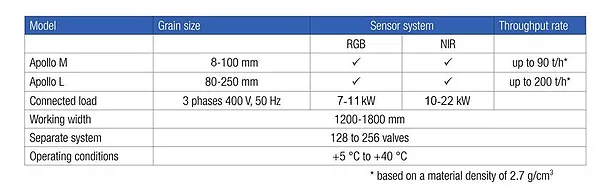

The sorting technology from OptoSort works across various efficient levels and is suitable for grain sizes from 8-250mm. Depending on the requirements, the bulk material is fed to the sorting device via a vibrating chute and slide. The assignment of the sorting material takes place on the vibrating unit where the material is distributed into a monolayer and accelerated through a slide. In freefall, it is scanned, analysed and discharged through individually controllable nozzles. The separate product stream must be transported away after sorting.

-

Industrial minerals such as limestone, talc, calcit

-

rock salt, quartz, fluorite, magnesite

-

Precious metals such as gold or platinum ore

-

Metal ores such as copper, nickel, zinc, tungsten

-

Fuels such as coal

-

Slag from stainless steal, copper or ferrochromium

-

Secondary materials

Colour sorting- The colour sorting technology of OptoSort® series Apollo consists of high resolution line scan cameras and allows sorting according to colour, shape, size and texture. The DUAL technology allows scanning from two sides simultaneously, covering more than 80 percent of the partical surface.

Hyperspectral imaging - For materials that do not have any visible differences in colouring, hyperspectral imaging could be the technology of choice.

Selective metal sensor - Is used to detect metal parts in a bulk material flow and to classify them according to their conductivity and permeability.

Furthermore, OptoSort's in-house service technicians are available for constant servicing, inspection and update of hard- and software in the machines delivered, as well as supporting clients via remote maintenance.